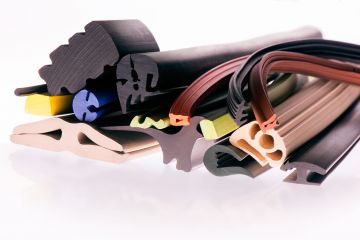

Profiles, rings and frames of rubber

You have the idea, we have the material-related solution

Profiles, rings andframes

Profiles, rings and frames

When it comes to sealing, damping and insulating, rubber profiles for diverse applications in industry, community and commerce are functionally developed, designed, produced and supplied by us. We also undertake the processing into ready rings and frames.

For decades, we are specialized in technical tasks, soluted by profiles made of soft rubber or foam rubber FKM (Fluorflex +). We use our knowledge for functional-, material- and production-oriented solutions.

For each application, depending on the needed quatity, size requirement and function, we offer the appropriate materials and manufacturing processes. Our design department-appended tooling allows almost any geometry and ensures short reaction times.

Our profiles, rings and frames find use in: machine industry, building industry, automotiv industry, heating and ventilation industry, shipbuilding, home appliances, wind turbines, hydroelectric, air conditioning and much more.

Extrusion products for technicalapplications

Product development

Our profiles are not standard products, the are developed according the desired function in coopertion with our customers.

The cross-sections are designed meeting the material- and production requirements and consider the use of deformation zones. The good restoring values support constructively designed seal geometries or fortifications.

- We develop, construct and assemble extrusions according to your tasks

- The focus is on function and efficiency

Manufacturing processes

For each quantity and all cross sections we have the appropriate equipment and procedures. Tailored to your needs, we use for small and medium quantities and large-volume profiles the conventional process with vulcanization in autoclaves or for stretched, small-volume profiles in long lengths continuous vulcanization in a heating channel.

- Conventional vulcanization for small quantities and mostly large-volume profiles

- Continuous vulcanization for small cross-sections and larger amounts

Extrusion technology

The production of rubber profiles is done in several steps. The extrusion forms the mixture into an already accurately profiled semi product.

By screwing the mixture is plasticized, an established uniform mass pressure is built and it´s pushed through the profile-providing tool. Despite most different cross-sections, a straight discharge of the raw profile must be achieved through a uniform flow behavior.

- Mix as cut, endless feed strips

- Uniform mass pressure and speed

- Exactly profiled semis

Continuous vulcanization

Our continuously working machine for stetched small volume profiles has two extruders and an electrical hot-air channel for the vulcanization.

It is suitable for large series, the use of multiple tools and products with high dimensional accuracy. We produce profiles of soft rubber and

FKM sponge on it.

- Extruder with screw diameters of 90 and 45 mm for many profile cross-sections

- Fluor sponge „Fluorflex+“

Conventional production

The production with conventional vulcanization is suitable for small, medium as well as for large series production and especially for large cross-sections. The profiles are vulcanized after profiling either round or stretched lying in the autoclave. Profiles that are to be installed in use with tight radii without tension, already obtain their desired shapes by the vulcanization on templates.

- Screw diameter from 45 to 120 mm

- Profile cross-sections up to 200 mm width

- Stretched lengths up to 40 m

Performance by professional coordination of internal and external processes

Assembling of rings and frames

Extrudates usually become to-install components by adapted assembling only. In addition to cutting, punching and notching we also connect profiles to frames and rings by the process of wet bonding, cold and hot vulcanization. We are creating permanent and precise connections before and even after the vulcanization of rubber profiles

- Adapted assembling of Profiles

- Wet bonding, cold and hot vulcanization

- All procedures for process-reliable and economical production

Handmade connections

Connecting vulcanized profiles to rings and frames by adhesive or cold vulcanized rubber solutions. Connecting of raw profile blanks by assembling with solutions and following vulcanization with and without templates in the autoclave. For pneumatic applications we also use valves in hollow profiles.

- Crafted compounds before and after curing

- Precisely assembling with templates

Mechanical connections in molds

Connecting of already vulcanized profiles even with different profile cross-sections by vulcanization in electrically heated molds. Also caps and other fittings can be molded in injection molds. For frames and rings made of profiles with hollows valves kann be fittet during the vulcanization.

- Bonding vulcanized profiles

- Connecting of profiles with different cross-sections

- Molding of caps and fittings